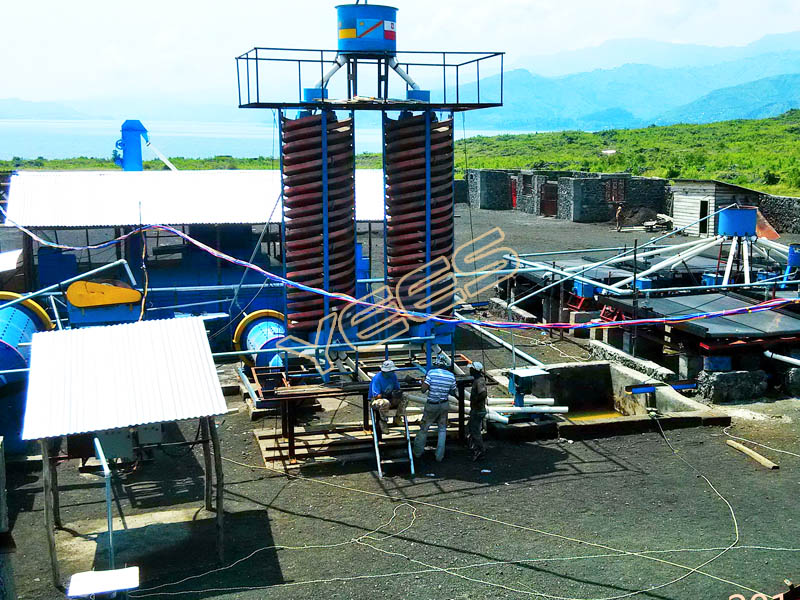

10t/h tantalum processing plant in Congo, The raw ore is gangue ore, containing some weathered mud ore. The tantalum and niobium ore crystals are fine, but the specific gravity is heavy.

According to the above mineral characteristics, we tailor-made tantalum and niobium mineral processing design. First, the raw ore enters the PE jaw crusher for rough breaking, then enters the hammer mill rock crusher for fine breaking, and then enters the trommel screen for washing and screening. Materials less than 2mm are directly sent to the spiral chute for roughing. Materials bigger than 2mm are sent to the ball mill for grinding and then flow into the spiral classifier. Return sand is sent to the ball mill by belt conveyor for re-grinding, and overflow is sent to the spiral chute by slurry pump for roughing.

The middling obtained by the spiral chute is coarse particle size and incomplete liberation, which needs to be grinding by another smaller ball mill before returning to the spiral chute for separation. The concentrate obtained from the spiral chute is sent to the shaking table for cleaning, then the rough concentrate is obtained.

After the rough concentrate is dewatered and dried, it is purified by the dry magnetic separator and the electrostatic separator, finally the qualified concentrates are obtained. The tantalum-niobium ore processing plant adopts the principle of first separation, first collection, and adopts two stages of grinding to prevent the loss of tantalum-niobium ore crystals caused by over-grinding.

Our company specializes in the production of all kinds of mining equipment, mineral processing equipment, mineral washing equipment, etc. We offer high quality products, perfect one-stop solution service, welcome customers to inquire.

WhatsApp:0086 187 7077 3971 | Email:rocky@yeesjx.com | Wechat:Rocky1980

Copyright © Yees Mining Equipment Co., Ltd. all rights reserved.