Multideck shaking table is also called four layers shaking table concentrator, three layers shaking table or triple layers shaking table machine, compared with single layer shaking table, it has same separation index, but can get many times processing capacity in a similar floor area. Multideck shaking table is used in a variety of applications: 1. Separate 0.02-2mm tungsten ore, tin ore, tantalum ore, niobium ore or other non-ferrous, rare and ferrous metal minerals; 2. Separate 0.5-6mm coal or 0.5-1mm coal slime; 3. Separate 0.2-0.3mm coal gangue or pyrite slime; 4. Separate useful minerals from other mixing substances which has sufficient density difference and at appropriate particle size.

Multideck shaking table working principle

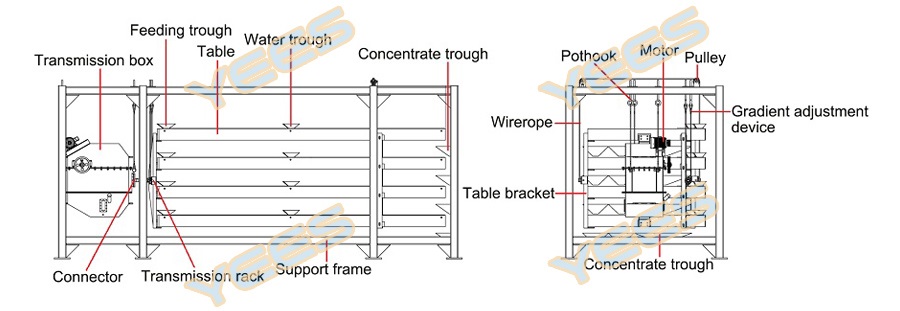

The structure is shown in the following figure; transmission device and table are respectively suspended on the steel frame with steel wire rope. The transmission device uses new type of multi-eccentric inertia gear, it's connected with multilayer table by a reinforced connector. Table is made of high-density fiberglass and high-quality emery. Self-locking pulley slope adjusting devices are set on the steel frame, pull the steel wire rope to adjust the inclination angle and lateral slope of the table. The movement track of the multilayer shaking table is the same as the single layer 6S shaker table, so the principle of mineral layering and zoning is also the same. The slurry is evenly sent to each table by the top distributor, after separation the concentrate, middling and tailing are collected by the receiving trough of each layer and finally discharged uniformly from the lowest layer.

Multideck shaking table diagram

Advantages and features

1. Compared with the single layer shaking table, it can save the occupation area, save the foundation construction investment, reduce power consumption, suitable for large scale use;

2. Multi-layer structure, easier to arrange material feeding and products collecting;

3. Suspension structure, no vertical excitation force, no vertical jump. Tiny vibration let it can be installed on the high-rise floor;

4. Suspension structure, minimal friction, few wearing parts, easy maintenance;

5. Easy operation and management;

6. Fiberglass and emery table, high rigidity and strength, no deformation, no crack, rust resistance, corrosion resistance, wear resistance and strong climate adaptability.

Application case video

Tin ore processing plant: https://youtu.be/nUSG_oOZJfs

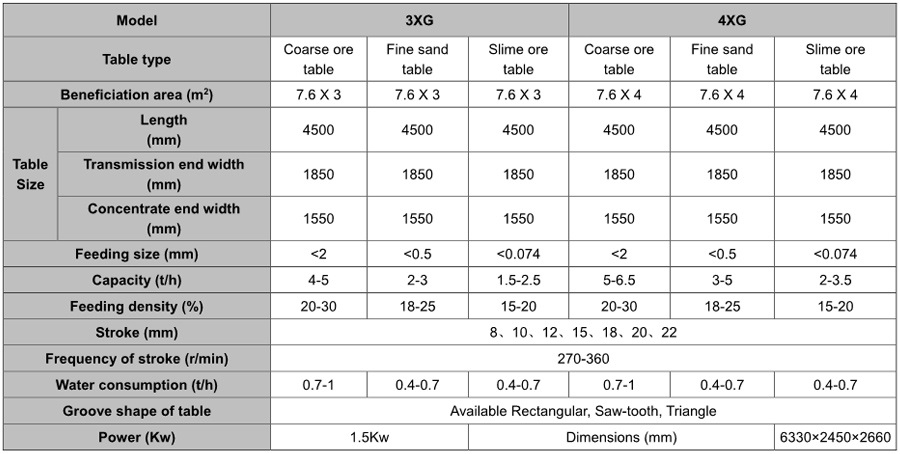

Main technical parameters