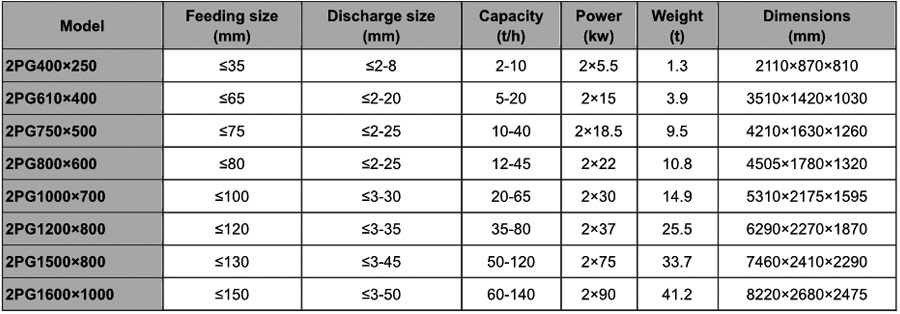

Double roll crusher is suitable for the secondary crushing or find crushing of the hard, medium hard and soft materials which the compression strength less than 300Mpa and the moisture content less than 35%. It can be widely used in mining, thermal power, cement, ceramics, metallurgy, chemicals, building materials, etc. This machine has the characteristics of low maintenance cost, reliable performance, little dust and low voice.

Double roll crusher has two abrasive rollers. According to the user’s demand, the roller surface is divided into flat surface and toothed surface of two models. If the hardness of material is bigger than 200Mpa, we should use the heavier model.

Flat double roll crusher is suitable for the fine crushing which requires the feeding size less than 80mm and the range of discharge 0.3-20mm. Such as: The crushing of pebbles or construction waste in the sand making industry; The crushing of iron ore, manganese ore, quartz stone, etc. in the mining industry; The crushing of raw material in the ceramic industry; The crushing of coke or quicklime in metallurgical industry; The crushing of fine pulverized coal in the coking plant; The crushing of various raw materials in the chemical industry; Other crushing occasions and so on.

Toothed double roll crusher is suitable for the medium fine crushing which requires the feeding size less than 110mm and the range of discharge 3-30mm. For example: The pre-crushing of cement clinker, limestone and composite materials before the grinding in cement industry; The pre-crushing of steel slag, iron ore or manganese ore before the grinding in the mining industry; The crushing of all kinds of construction cement or gravel in brick factory; The crushing of coal in the thermal power plant; Other crushing occasions and so on.

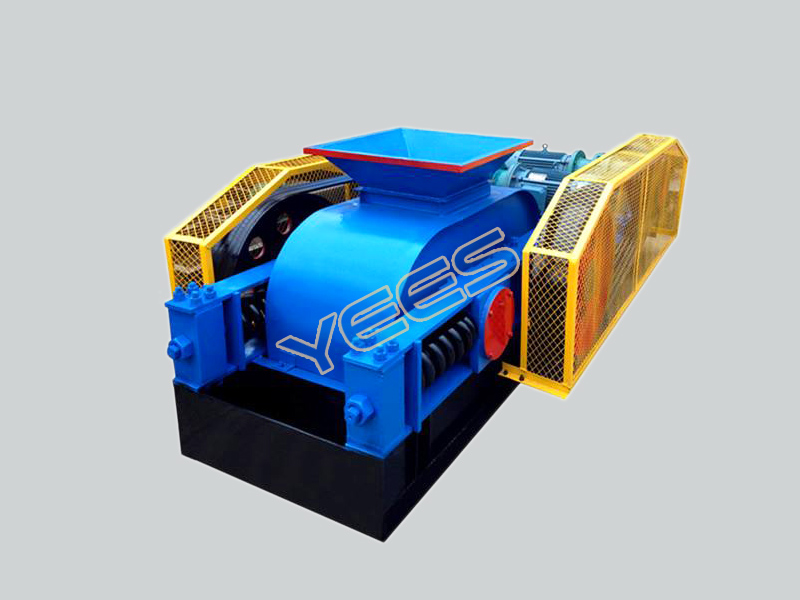

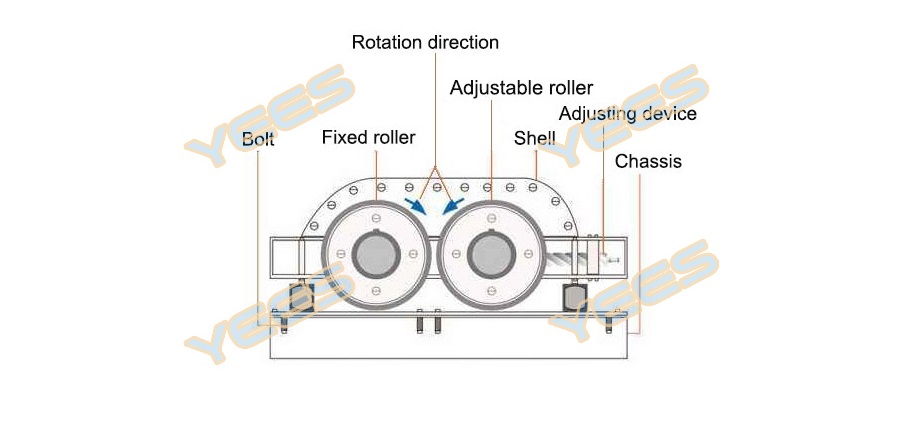

Double roll crusher working principal

The machine is fixed with two high-strength wear-resistant alloy rolls. After the material enters the gap between two rollers (v-shaped crushing chamber), it is subjected to the extrusion pressure and shear force generated by the relative rotation of two rollers. Under the influence of extrusion, shear and grinding, the material is broken into the required size and discharged from the lower part of the machine through the outlet. In case of the material which is too hard or unbreakable, the roller can be automatically moved backward by the role of the spring, so that the gap between the rollers increases, the hard or unbreakable material fall down, thus protecting the machine. The product discharge size can be controlled by adjusting the gap of two rollers.

Double roll crusher diagram

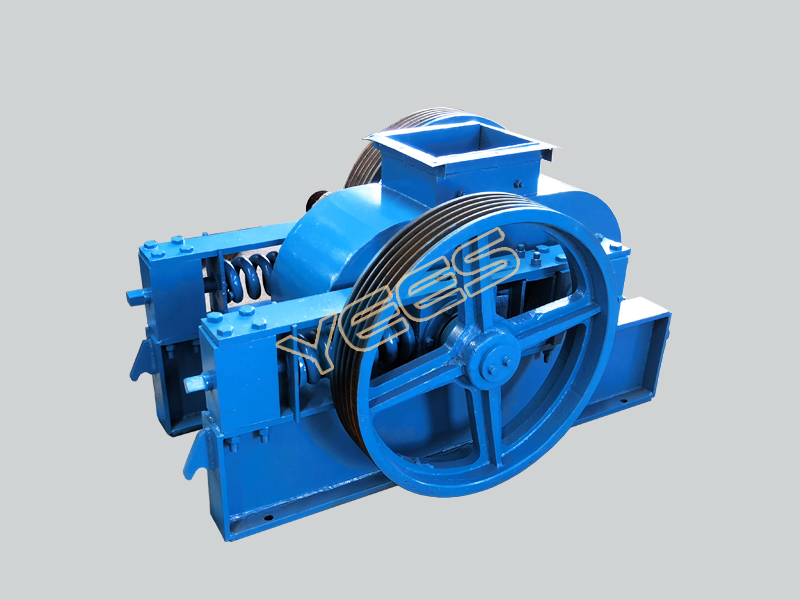

Advantages and features

1. Small volume, large crushing ratio;

2. Low noise and less dust;

3. Uniform particle size and low over-powder crushing rate;

4. Sensitive overload protection, safe and reliable;

5. Less wearing parts, long service life.

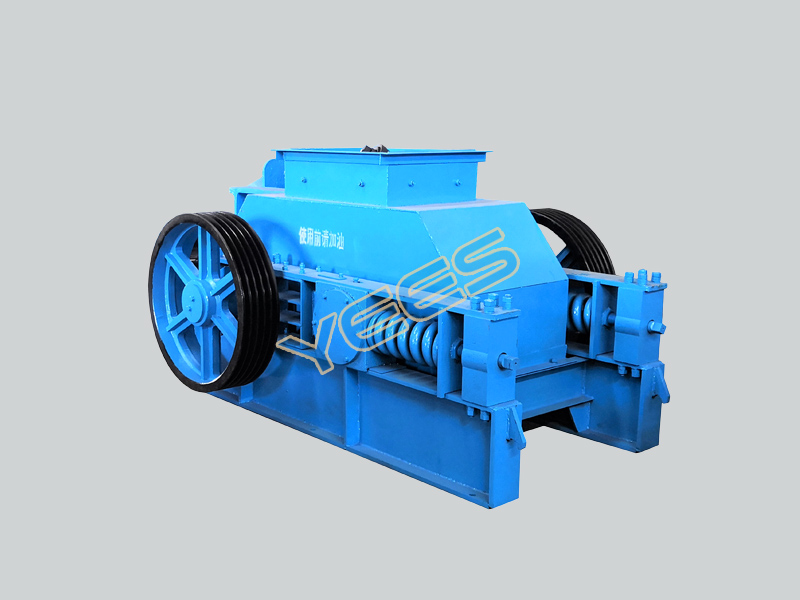

Main technical parameters