Three disks high intensity magnetic separator belongs to the electromagnetic magnetic separator, which uses current to generate magnetic field through the excitation coil. The magnetic field intensity can be from 0 to 18000Gs. It's suitable for the separation of mixed magnetic minerals. According to the magnetism difference of minerals, it can achieve the perfect one-time separation of various minerals, through adjusting the current of each excitation coil to forms the different intensities of magnetic field, or through adjusting the interval of each disk and materials (belt) to obtain different induction intensities of magnetic field. Because it has three magnetic disks, so strong magnetic materials, weak magnetic materials, non-magnetic materials and other minerals can be separated at one time. This equipment is widely used in the dry separation of tantalite, niobite (columbite), tungsten, tin, ilmenite, monazite and other magnetic and non-magnetic minerals.

Three disks high intensity magnetic separator working principle

During the work, the materials fed into the hopper. The ferromagnetic materials will be removed by the permanent magnetic drum. The rest of minerals will be uniformly sprayed onto the belt conveyor (The mineral thickness generally between 0.2-0.8mm). When the machine is running, the belt conveyor will send the minerals down below the magnetic disk, where the paramagnetic minerals will be quickly absorbed onto the tooth tip of magnetic disc. When the magnetic disk rotates to the low-intensity magnetic area, they will fall into the concentrate bin under their gravity and centrifugal force. The non-magnetic minerals will be conveyed to the tailing bin via belt conveyor and discharged. The intensity of magnetic induction of each disk and the interval of magnetic disk and material can be adjusted according to the specific magnetization coefficient of minerals.

Advantages and features

1. Compact structure and small occupation area;

2. Easy installation and maintenance;

3. Stable parameters and easy operation;

4. Suitable for dry operation in arid region.

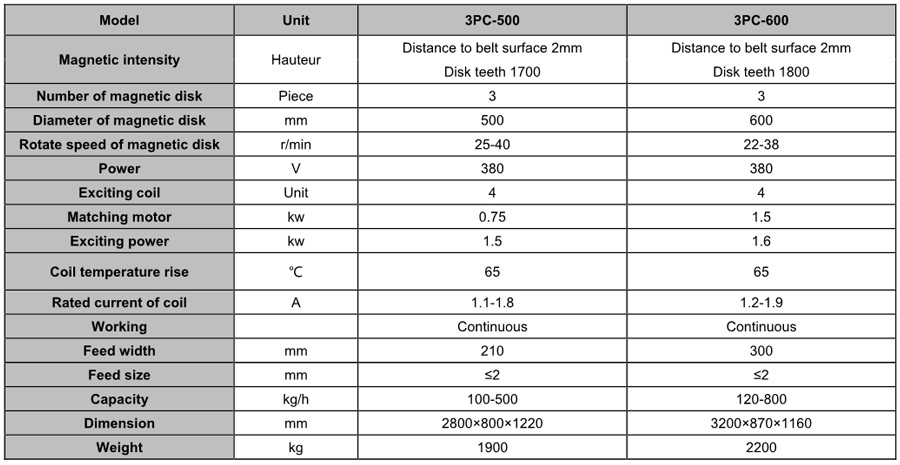

Main technical parameters