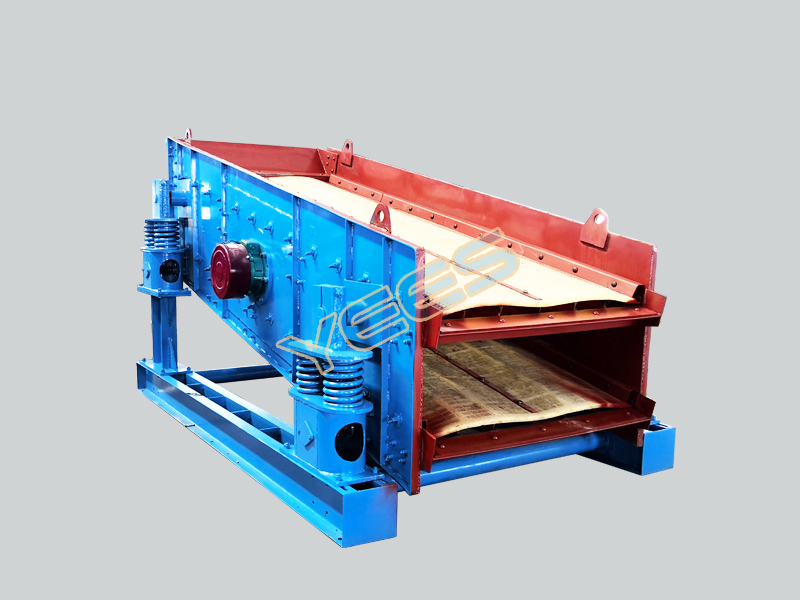

YSC circular vibrating sieve machine absorbs the advantages of YA series and YK series circular vibration screen. It uses side plate vibration motor as the excitation source, it is a new type of vibrating sieve separator. It is widely used for the classification or dewatering of various materials in hydropower, coal, metallurgy, mining, building materials, chemical industry and other industries.

YSC circular vibrating sieve machine working principle

YSC circular vibrating sieve adopts side plate vibration motor as vibrator to replace the pulley type eccentric block, no side plate bearing. The centrifugal force is directly generated by the side plate vibration motor, which stimulates the screen box to produce circular motion with certain amplitude. The material on the screen is subjected to continuous throwing motion on the inclined screen surface by the vibration of the screen box. When the material touches the screen surface, the particles smaller than the screen hole pass through the screen hole, so as to achieve classification.

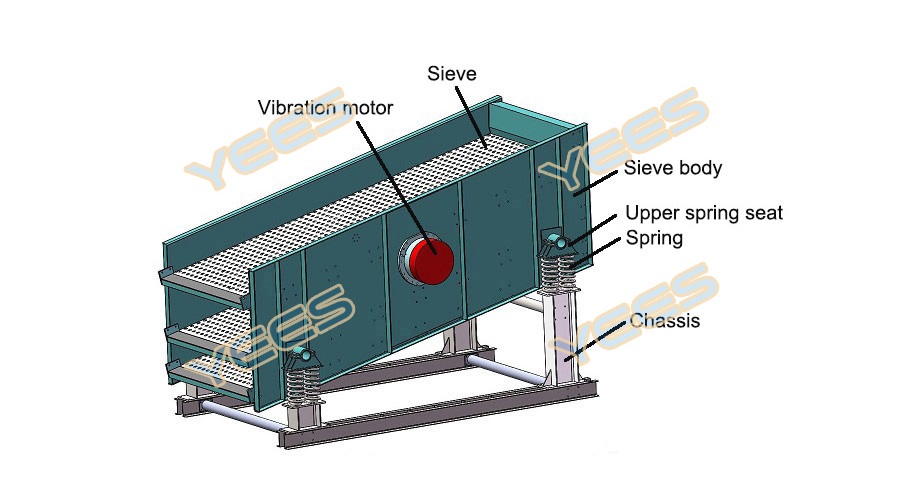

YSC circular vibrating sieve machine diagram

Advantages and features

1. High quality side plate type vibration motor is used as the excitation source, and the vibration motor is installed on the side plate. The machine has good stress and long service life;

2. Advanced technical parameters, large processing capacity and high screening efficiency;

3. Simple and compact structure, good strength;

4. The side plate is equipped with reinforcing plate, and several seamless steel tubes are used as beams to strengthen the rigidity of screen box. Riveted assembly frame, which improves the service life of the equipment;

5. Adopt rubber spring to reduce vibration, smooth operation and low noise;

6. Easy maintenance.

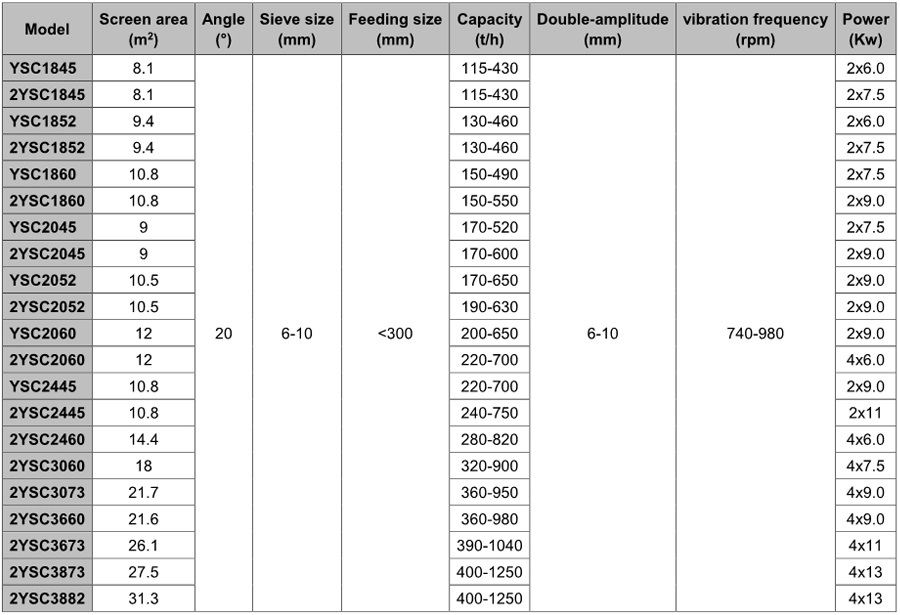

Main technical parameters

According to the number of screen layer and screen mesh area is divided into single layer, double layer, double layer and double group, according to the user’s needs can be designed three-layer and multi-layer structure. There are two kinds of structures, one is with receiving box and the other is without receiving box.