Product introduction

ZSW vibrating feeder is configured before primary crusher, it can continuously and uniformly transport large blocks of materials, while removing soil, impurities and controlling the feeding amount in order to match with the capacity of subsequent crushing and screening production lines. It is the necessary equipment to ensure the quality and quantity in the crushing and screening production line. It is mainly used in mining, crushing plant, grinding station, cement plant, glass plant, ceramics plant, chemical plant and other industries.

ZSW vibrating feeder working principle

The equipment uses the rotation of eccentric block in the vibrator to generate centrifugal force, makes the tank body, vibrator and other movable parts to do the forced continuous circle or approximate circle movement. The materials are continuously thrown along the inclined tank surface by the vibration of tank body, and the materials are continuously and evenly sent to the feeding hole of the subsequent equipment. When the tank body and the material move forward, the material in the hopper then fills the spare space in the screen box. When the tank body moves backward, the material on the screen surface cannot be returned because jam at back, then it’s forced to pour out at the edge of feeder to achieve the feeding. The feeding amount can be adjusted by changing the amplitude and frequency of vibrator or the opening of the feeding gate.

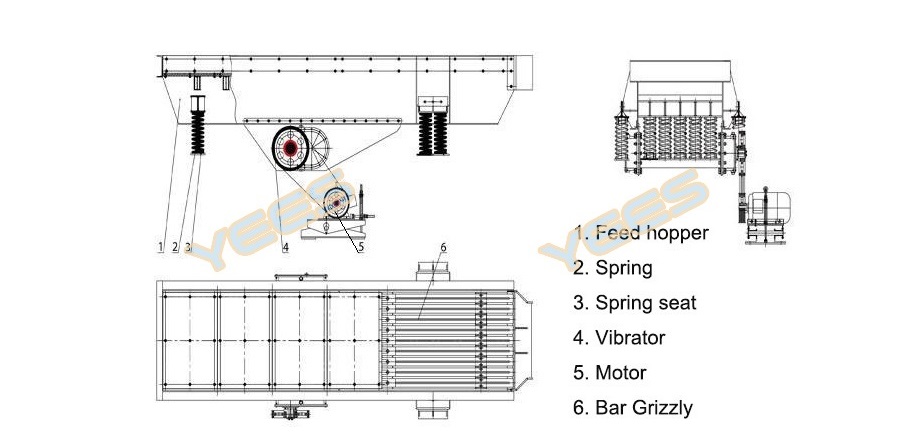

ZSW vibrating feeder diagram

Advantages and features

1. Large feeding size, large capacity;

2. Compact structure, stable vibration and reliable running;

3. The tank body is equipped with cast iron lining plate, wear resistant and long service life;

4. The material can be pre-screened to remove various impurities.

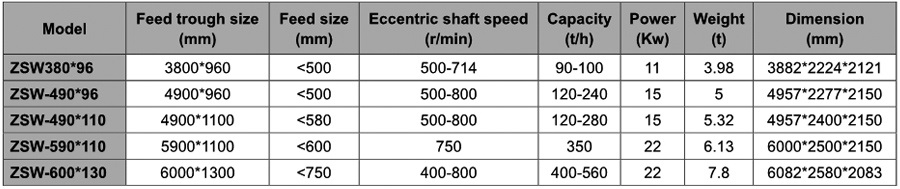

Main technical parameters