Wet high intensity belt magnetic separator is a new type of magnetic separation equipment, which is designed and developed with physical mechanics, fluid mechanics and magnetic, it has ultra-high magnetic field intensity, the highest magnetic field can reach 15000Gs. The wet high intensity plate magnetic separator is mainly applicable to the separation of weak magnetic minerals of particle size less than 5mm; And the iron removal from non-metallic minerals: such as manganese ore, ilmenite, chromite, wolframite, tantalum and niobium ore, hematite, pyrite, limonite, siderite and other metallic minerals separation; And such as the iron removal from mica powder, quartz sand, potassium feldspar, nepheline, fluorite, siliconite, lithoclase, kaolin; It can also be used for iron removal in coal, non-metallic mineral, building materials and other industries.

Wet high intensity belt magnetic separator working principle

The equipment is mainly composed of support frame, high intensity magnetic plate, distributor, washing water pipe, belt, adjusting device and other structures. During the work, slurry fed through the pipeline into the distributor of magnetic separator, then it be uniformly scattered on the belt which is at the upper of magnetic plate. The slurry flows down along the downward direction of the inclined magnetic plate by gravity, the magnetic material in the slurry would be firmly adsorbed on the belt under the influence of strong magnetic force. The belt rotated up along the upward direction of the inclined magnetic plate by motor, at the same time, it takes the adsorbed magnetic mineral to the non-magnetic zone. The magnetic material will fall off by the washing water then discharged from the iron exit, and the non-magnetic slurry keep flow down along the downward direction of the magnetic plate then discharged from the non-magnetic exit.

Advantages and features

1. Uniform feeding distribution and perfect magnetic unloading: double-layer orifice plate, stable and uniform, makes thin material layer. Automatic magnetic material cleaning device, magnetic unloading clean;

2. Power saving and energy saving: only one small power motor, very low power consumption. Unique controllable design of water system, small water consumption;

3. Long service life: the belt is made of high-strength and high-quality composite material, with long service life and perfect magnetic unloading;

4. Frequency conversion speed: the speed of the belt is adjustable, which can achieve better iron removing efficiency by adjusting the belt speed according to the characteristic of material;

5. Adjustable plate slope: it can achieve better iron removing efficiency by adjusting the plate slope according to the condition of material;

6. Large magnetic plate area: large magnetic plate with a wide magnetic and gravity separation area. At present, the largest width for the panel is 2500mm, and its largest length is 3000mm;

7. The magnetic system is made up of the rare earth NdFeB magnets with high performance. It has a very wide poly pole face, lots of magnetic poles. It’s with a very high magnetic induction ability and a very high magnetic gradient. The magnetic intensity on some part can reach 17000Gs.

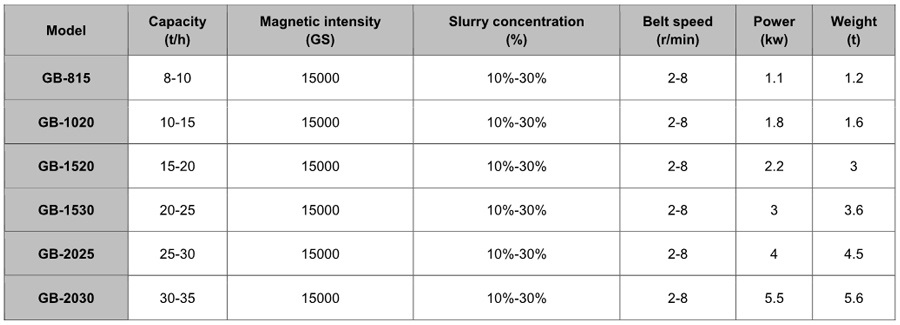

Main technical parameters