RCYD series self-discharging iron remover uses permanent magnet material as magnetic source, so as to achieve the purpose of high efficiency iron removing or iron separation. It can be used with various types of belt conveyor, vibration conveyor, chain plate conveyor, feeding chute and other conveying equipment together. The internal magnetic materials are all made of high strength rare earth NdFeb, it's a strong magnetic core, it has strong magnetic force which can easily absorb 0.1-35Kg of ferromagnetic stuff from the materials, thus effectively protect the crusher, grinding machine.

RCYD series self-discharging iron remover working principle

The equipment is composed of high performance permanent magnet core, iron removing belt, motor, frame, roller and other parts. When granular materials through right below the iron remover. The ferromagnetic impurities mixed in the material are sucked up, due to the belt is constantly rotating, the adsorbed ferromagnetic materials be thrown out to iron bin when they get non-magnetic area by centrifugal force, thereby achieving the purpose of continuous automatic iron removing.

Advantages and features

1. The magnetic circuit is designed by computer simulation, with perfect double-pole structure, high magnetic field intensity, large gradient and large attraction;

2. High performance NdFeb as a magnetic source, high magnetic energy accumulation, not easy to attenuate, the attenuation less than 5% within 8 years;

3. Groove drum structure, with automatic deviation correction function, fully sealed bearing seat, good sealing, can adapt to all kinds of harsh environment;

4. Automatic iron unloading guarantees continuous long-term trouble-free running.

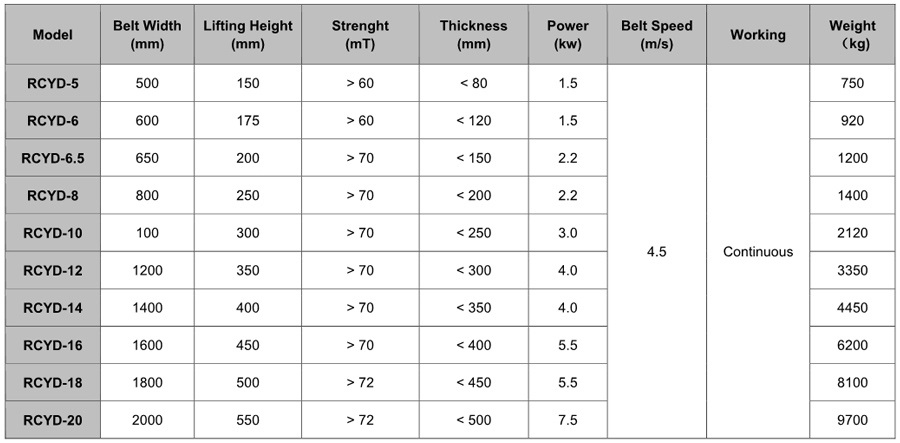

Main technical parameters